Common Challenges vs. Business Objectives

The Challenge

The Objective

Defects discovered too late

Catch issues at source

Manual, paper-based records

Fully digital system

Time-consuming root cause analysis

Reduce Cost of Poor Quality

Inconsistent inspection procedures

Standardize processes

Audit preparation takes weeks

Audit-ready 24/7

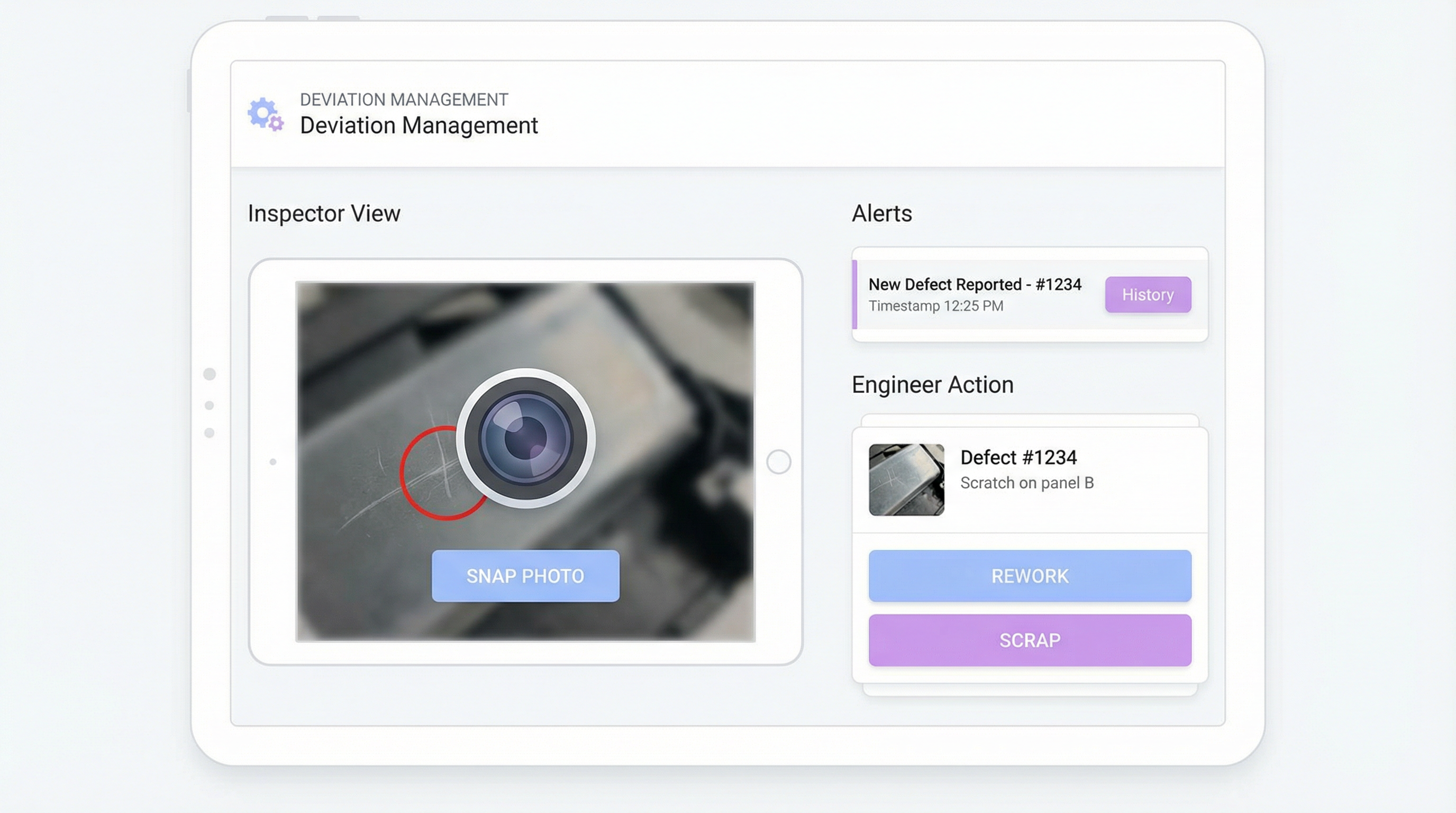

DEVIATION MANAGEMENT: Instant Decisions

"Inspector finds bad parts. They sit in quarantine while paper report travels to engineering."

Before (Manual)

- • Paper NCR filled out

- • Walked to engineering office

- • Sits in inbox for days

- • Production disrupted

Result: Quarantine pile-up

With ProssimaAI

- Digital NCR on tablet

- Intelligent Routing to engineer

- Context-rich decision support

Result: Resolution in hours

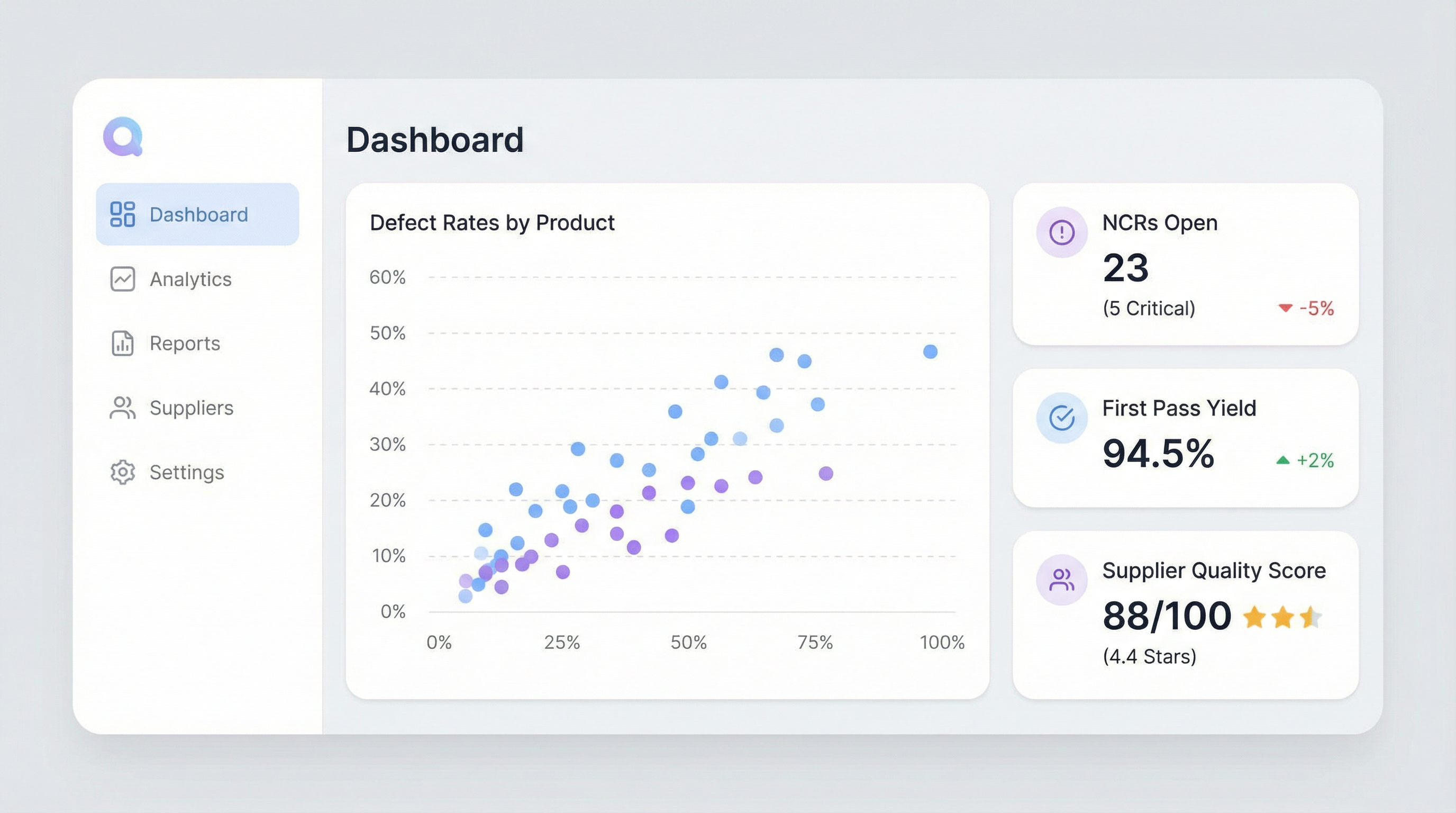

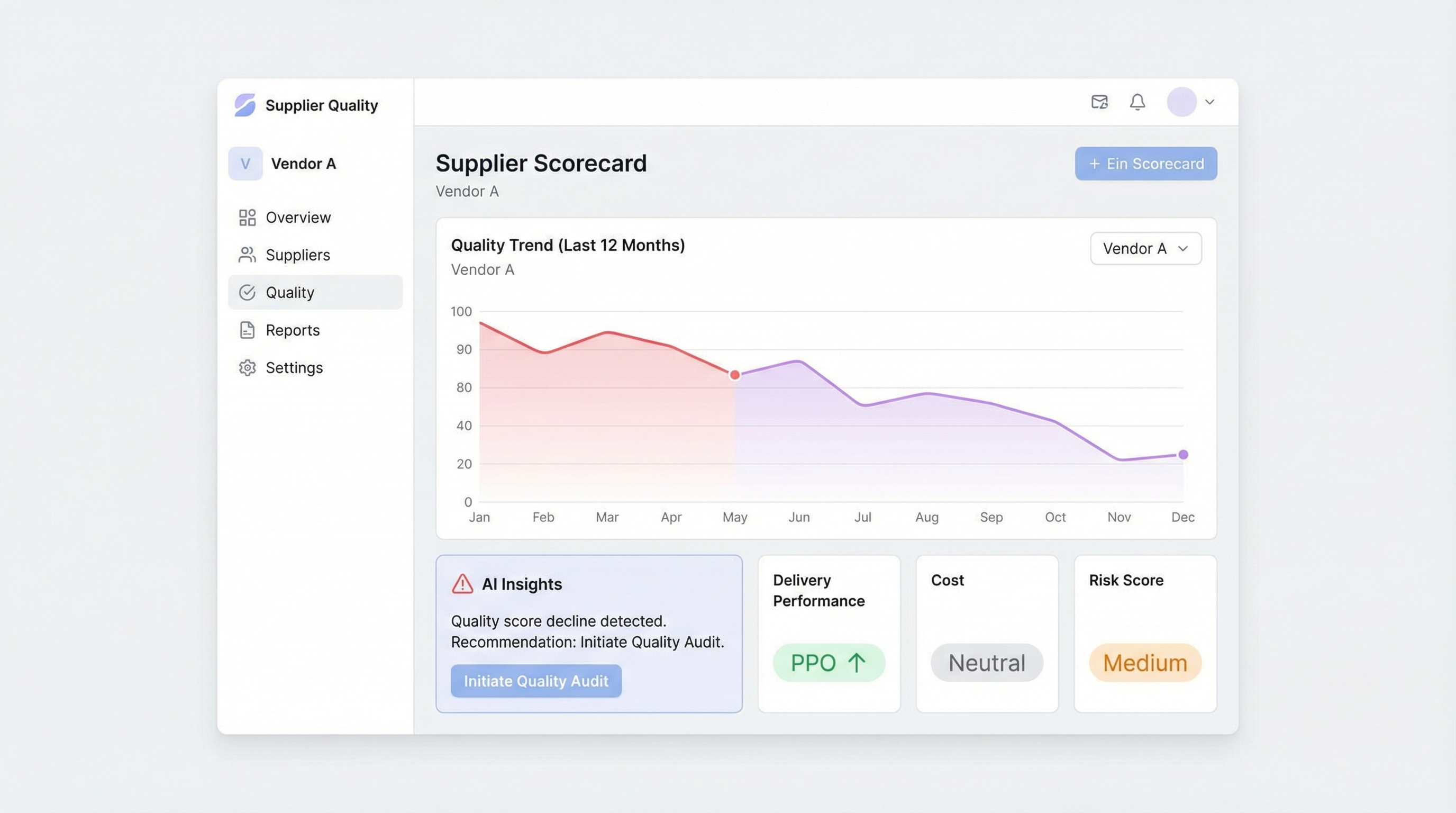

SUPPLIER QUALITY: Hold Them Accountable

"Bad raw material arrives. Rejection is manual, and supplier performance data is scattered."

Before (Manual)

- • Manual rejection note

- • Email to supplier

- • Credit note tracking on Excel

- • No data for negotiation

Result: Recurring quality issues

With ProssimaAI

- Auto-generated Rejection Report

- Real-Time Supplier Scorecards

- Predictive Quality Alerts

Result: Data-driven accountability

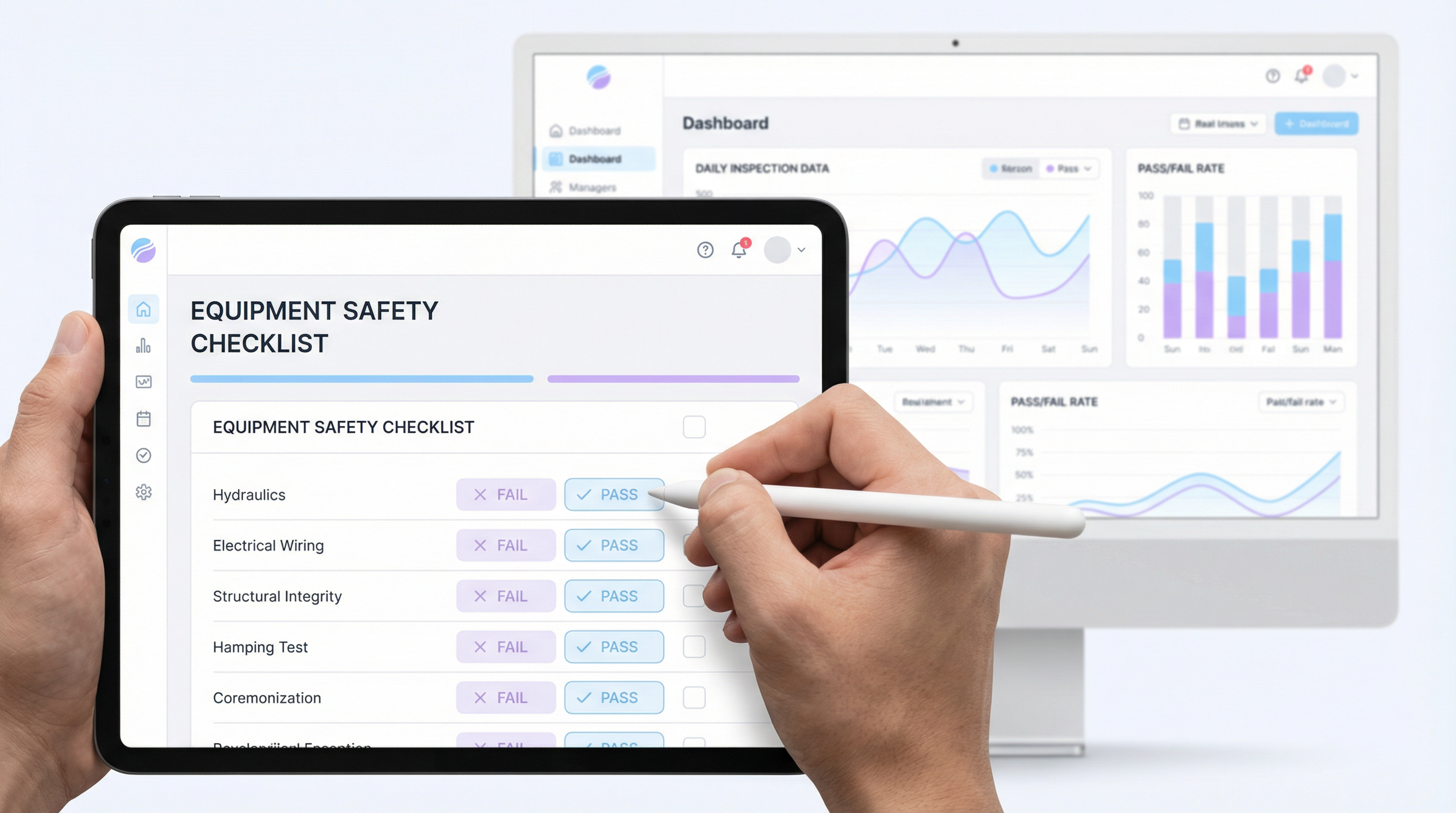

DOCUMENTATION: Go Paperless

"Thousands of paper inspection sheets stored in binders. Impossible to analyze or search."

Before (Manual)

- • Handwritten logs

- • Data locked in paper

- • Lost records common

- • Nightmare during audits

Result: Data graveyard

With ProssimaAI

- Digital Inspection Checklists

- Auto-save to cloud

- Searchable history instantly

Result: Actionable quality data

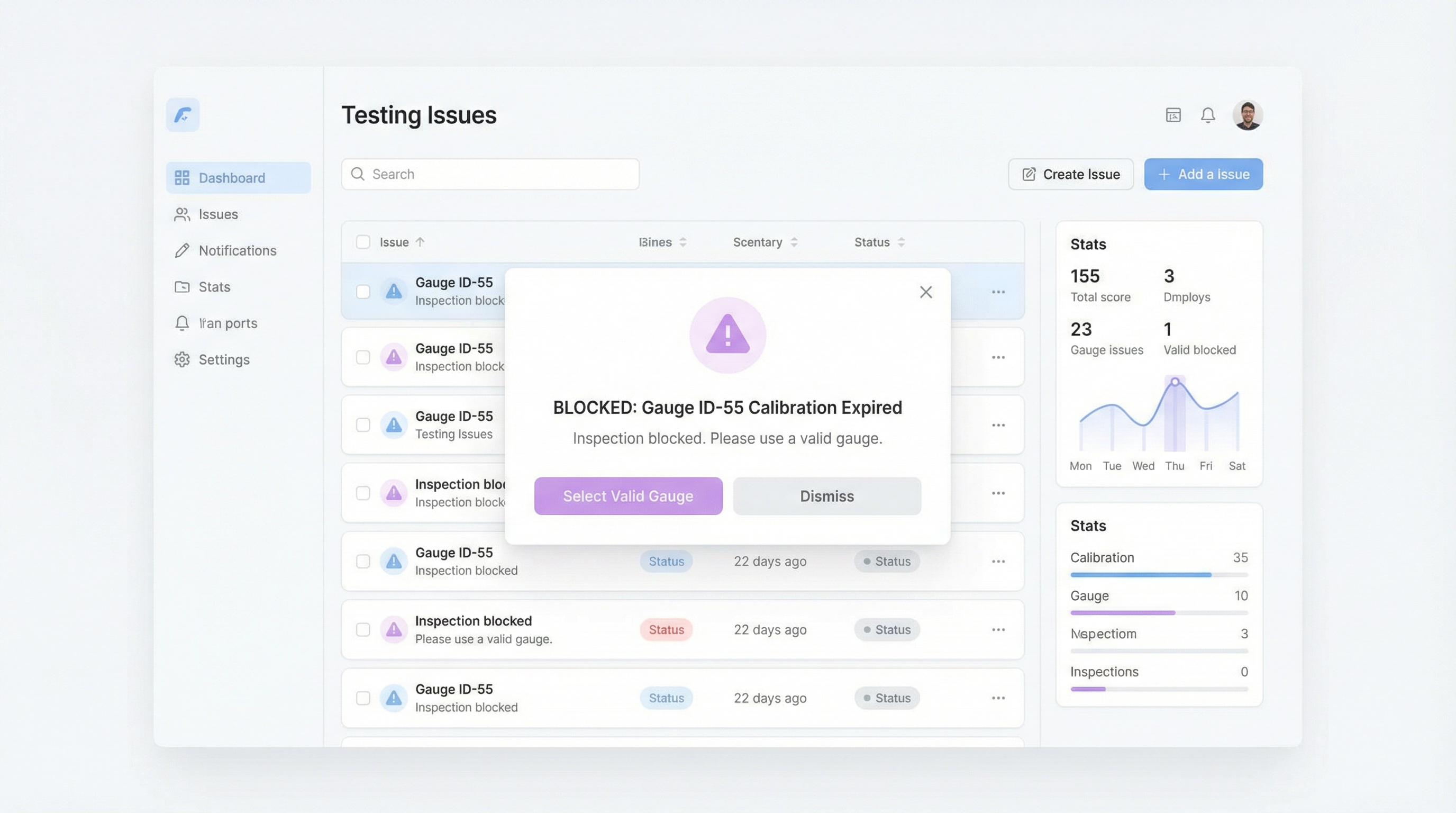

TESTING ISSUES: Ensure Calibration

"Inspector uses a gauge that is out of calibration. Entire batch has to be recalled."

Before (Manual)

- • Manual check of calibration sticker

- • Often overlooked in rush

- • Bad data collected

- • Costly recall

Result: Compliance failure

With ProssimaAI

- QR scan of tool before use

- Auto-block if calibration expired

- Digital calibration tracking

Result: 100% valid test data

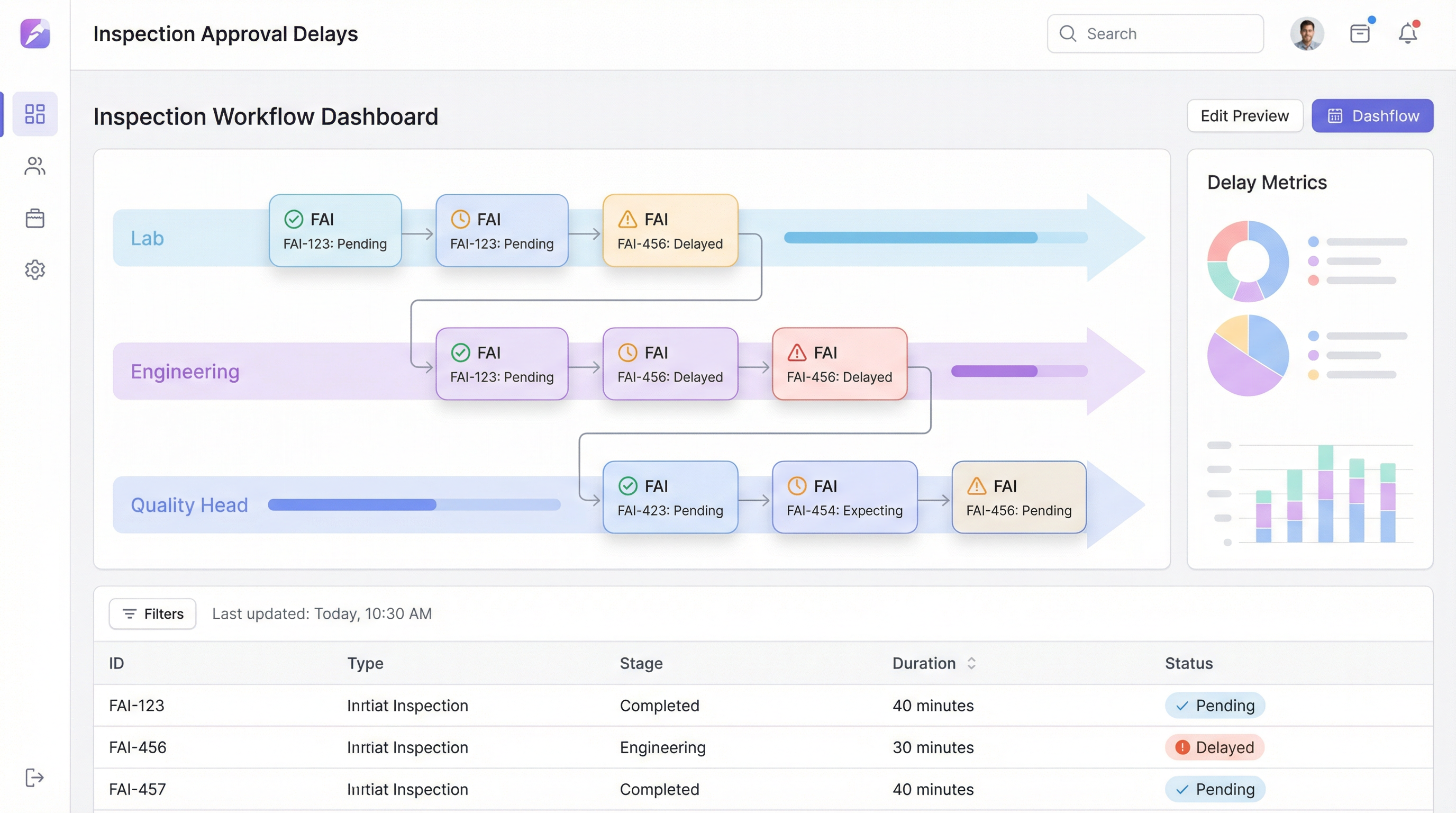

APPROVAL DELAYS: Speed Up Engineering

"PPAP or First Article Inspection (FAI) approval takes weeks, delaying mass production start."

Before (Manual)

- • Physical samples sent around

- • Paper reports lost on desks

- • Launch date missed

- • Customer unhappy

Result: Slow time-to-market

With ProssimaAI

- Digital FAI/PPAP workflow

- Parallel review process

- Auto-reminders for approvers

Result: Faster production launch

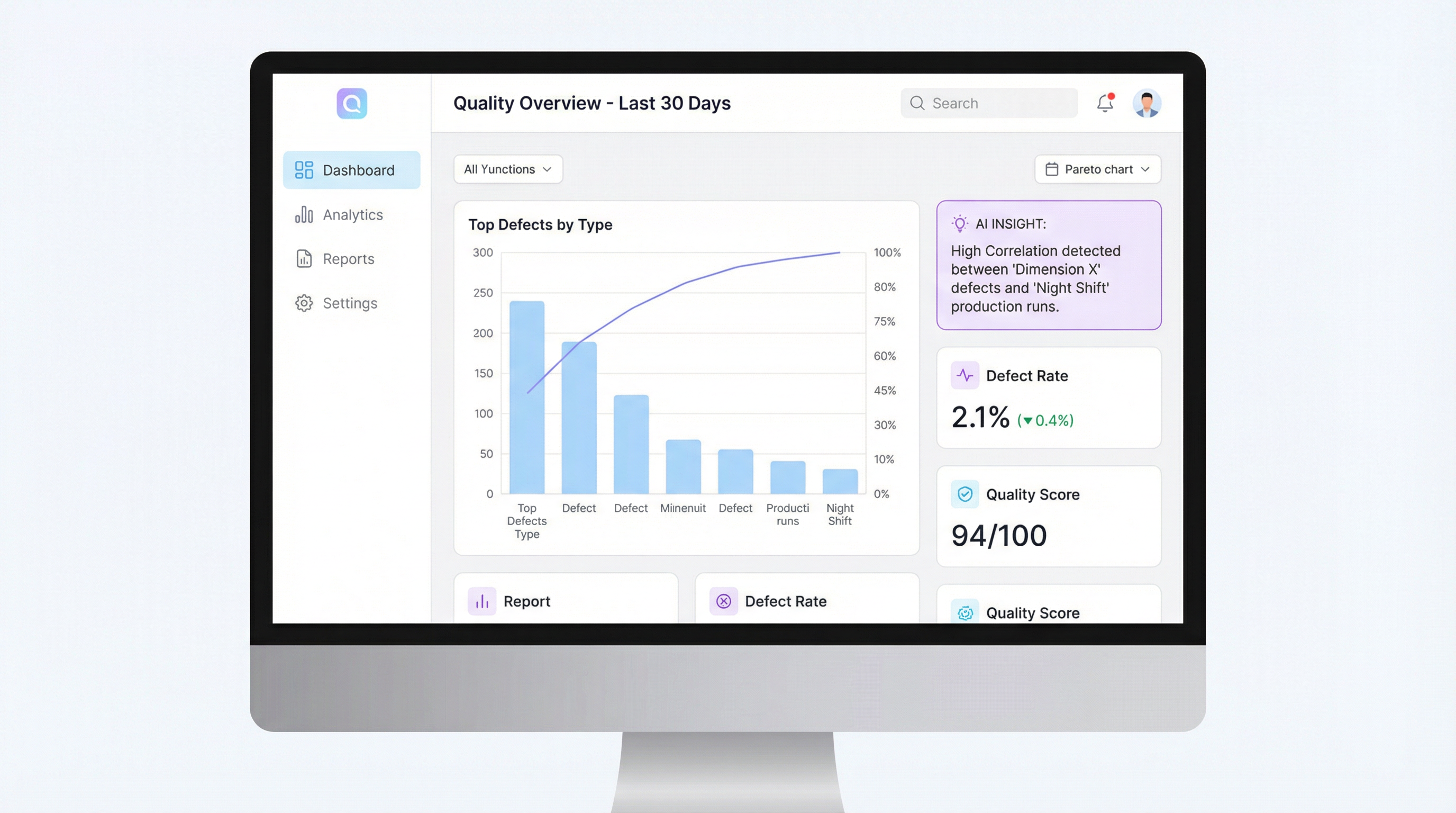

QUALITY ANALYTICS: Find Root Causes

"Defect rate spikes. No one knows why because data is on paper."

Before (Manual)

- • Manual data entry into Excel

- • Analysis happens weeks later

- • Root cause buried in noise

- • Problem repeats

Result: Recurring defects

With ProssimaAI

- Live Pareto Charts

- Correlation Analysis (e.g. Defect vs Shift)

- AI Root Cause suggestions

Result: Continuous improvement